Tool data management

Tool management in the Siemens 840D control. Tool list and description of the main parameters of the milling and turning tools.

INSIGHT

In this lesson we have started to talk about the Siemens 840D tool management. As this is a huge subject, but above all a fundamental one for operations, we will continue to talk about it in future lessons. In today’s lesson, we have looked specifically at the tool list and the main parameters associated with the tool. For the moment we are not going to create a new tool, we will do this in a couple of lessons when we have a clear idea of the data and parameters required for a correct tool definition. We will do this in a couple of lessons when we are clear about the data and parameters required to define the tool correctly, so at this stage let us concentrate on the data associated with the tool and firstly briefly review the steps to access data management.

There are two ways of accessing tool data, depending on the type of SIEMENS keyboard.

FIRST OPTION (all SIEMENS keyboards)

Press

Select the horizontal soft key PARAMETERS

SECOND OPTION (only for extended Siemens keyboards)

For some keyboards, there will be abbreviated keys for direct access to operational areas.

Press

Once we reach the parameter area, we will find three softkeys for tool management.

Let’s take a closer look at the description of the three tool-related soft keys:

|

Tool list to create, consult and search for tools. The tool list is a list of all configured tools and all geometric and technological data of each tool. |

|

The wear list reproposes the same table present in the list, specifically showing the fields related to wear corrections and tool life control management data. |

|

The magazine list shows the combination of tools and has specific functions for managing the loading and unloading of them. |

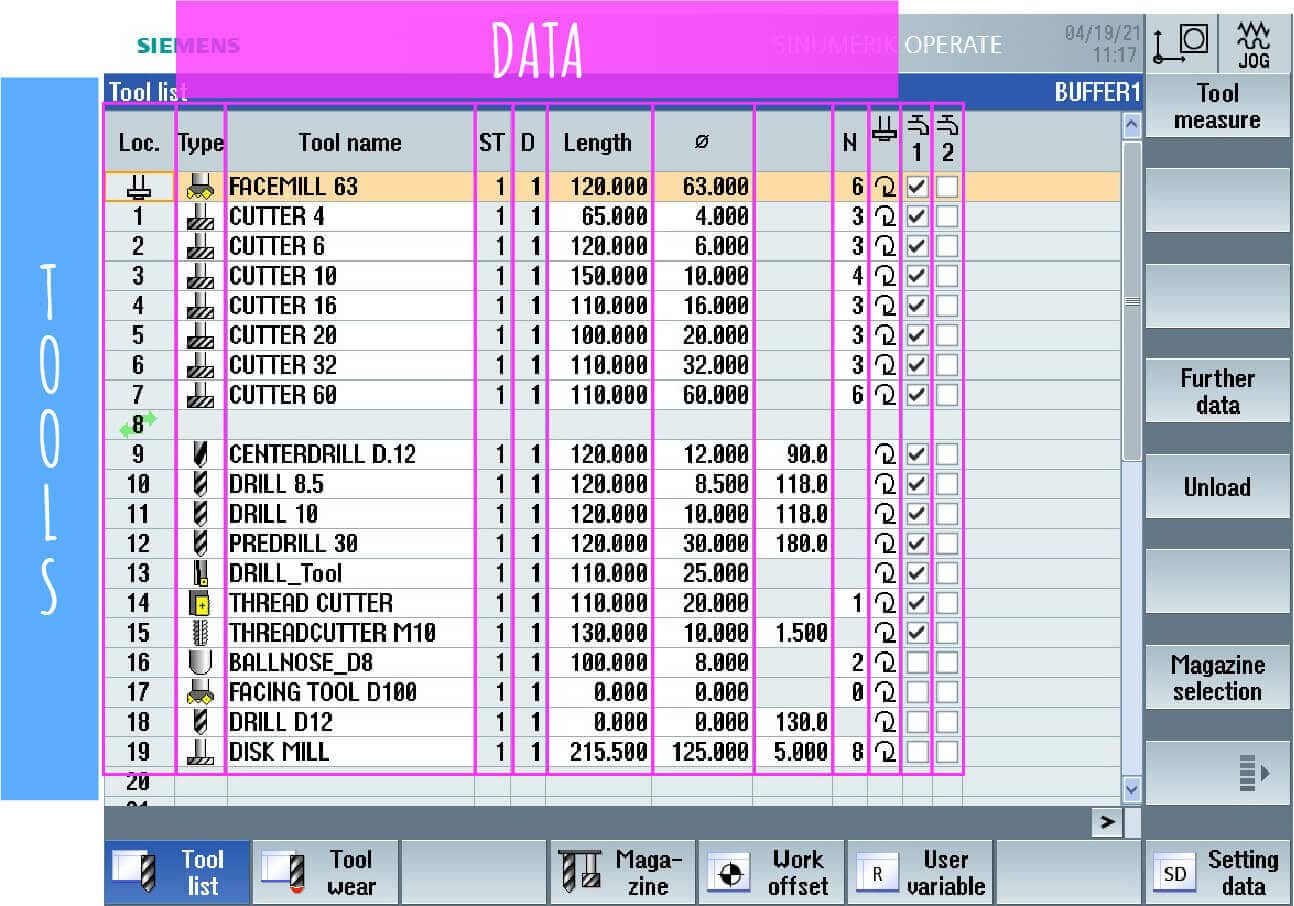

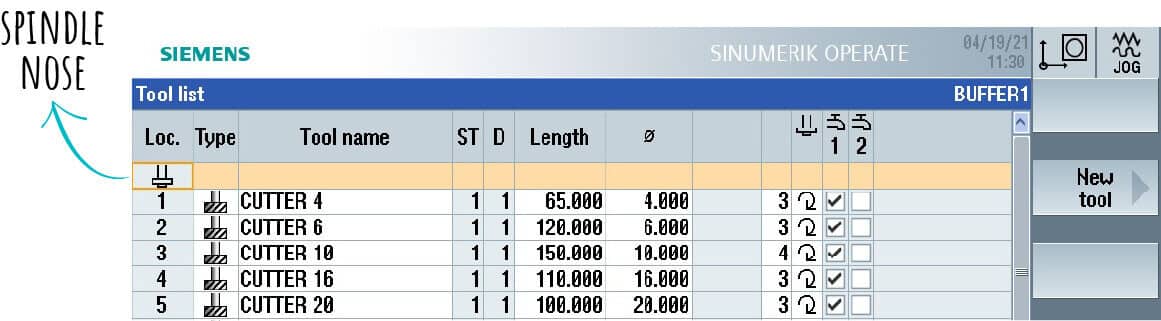

The tool list is a table consisting of tool in the lines and tool geometric/technological data in the columns.

MAGAZINE LOCATION

In the first line of the tool list you will find the magazine location where the tool is located. If the tool is in a place without a number, it means that it is configured but not mounted in the magazine. On the other hand, if the tool is in the line of place no. 1, it is in place no. 1 in the magazine. As far as milling cutters are concerned, in addition to the numbers in the “places” column we may find the spindle symbol or even the word “spindle”, indicating spindle nose. So the tool that will be in the row marked with the spindle symbol will be the one on the spindle nose.

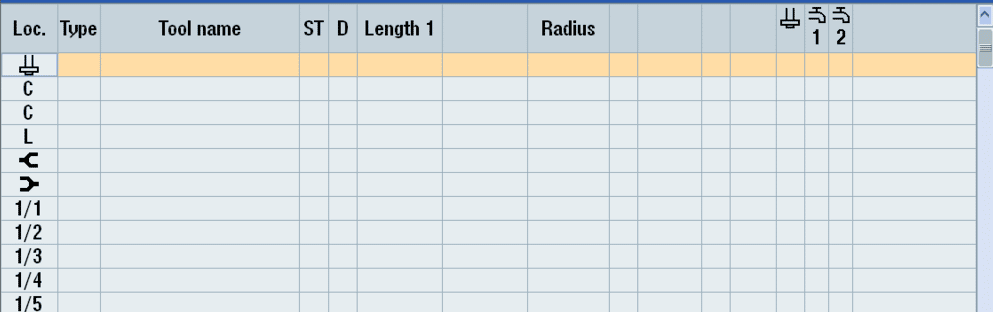

In addition to the spindle nose, we may have other lines just below the spindle that represent the intermediate places of the tool changer. In fact, some tool changers are structured to have cups that hold the tool for the next change. These holders do not belong to the magazine and since it is necessary to be able to track the position of the tool at all times, each manufacturer will create intermediate places in the tool list.

In the case of the image above, the magazine has two collets for tool change, in fact just below the spindle nose you will find the line dedicated to the tool mounted in CALIPER A and CALIPER B.

Or other manufacturers use the caliper symbol directly.

TOOL TYPE

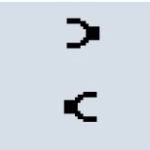

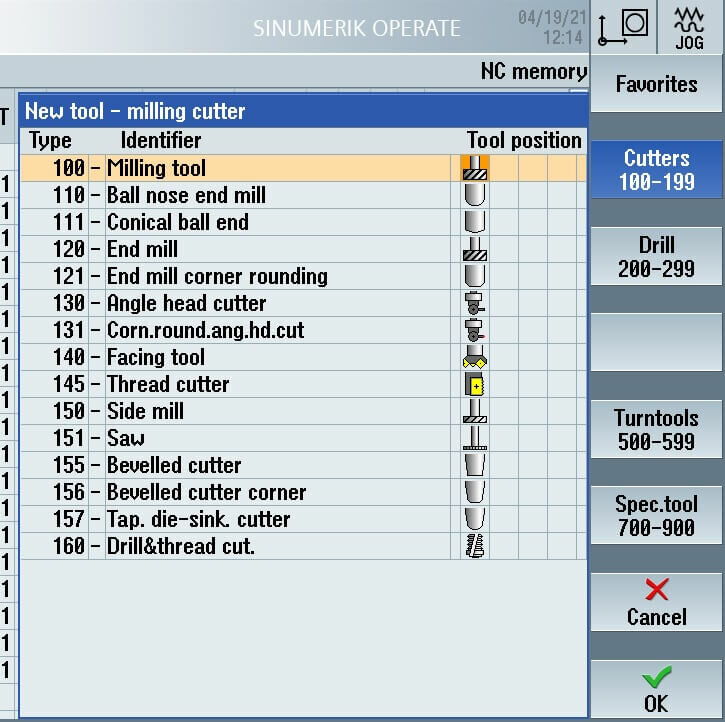

In the second column of the table there is a graphic symbol that represents the type of tool. When creating a new tool, the first thing to do is to choose the type of tool. In the vertical soft key bar we can choose the family to which the tool belongs.

TYPES OF MILLING TOOLS

|

The first family from the top is always the favourite family. This means that the most commonly used tool types are proposed. |

|

In the milling family we find all types of milling cutters. |

|

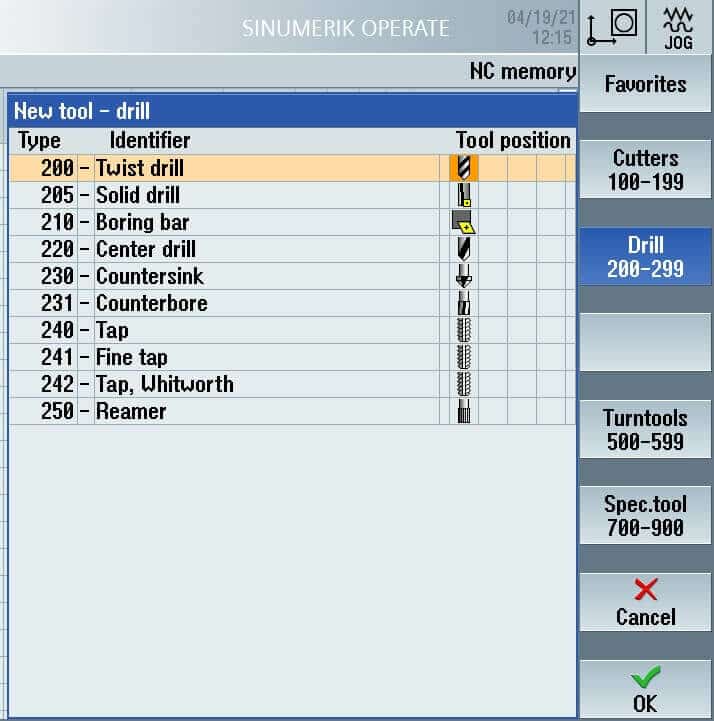

In the drill family, we can find the cylindrical drill, the countersinks, the taps and the boring tools. |

|

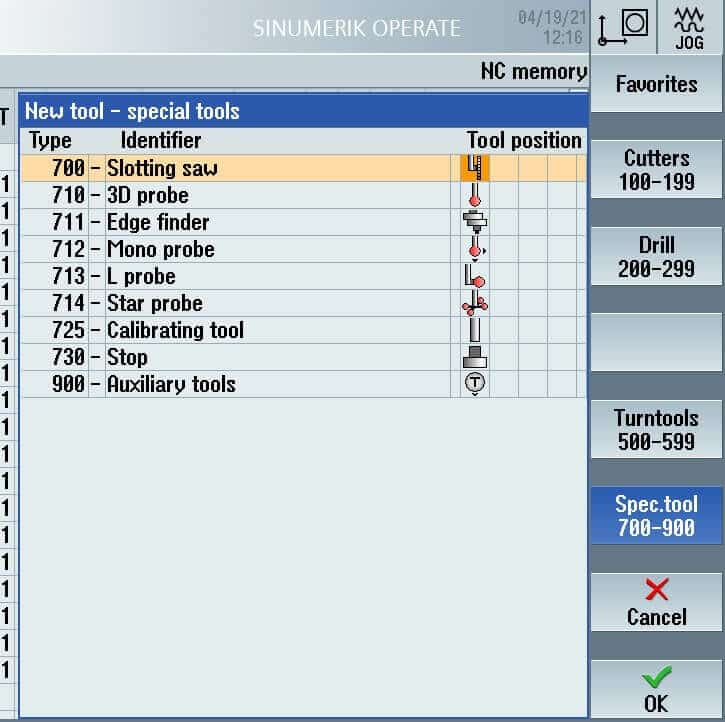

In special tools we mainly find all probing tools. |

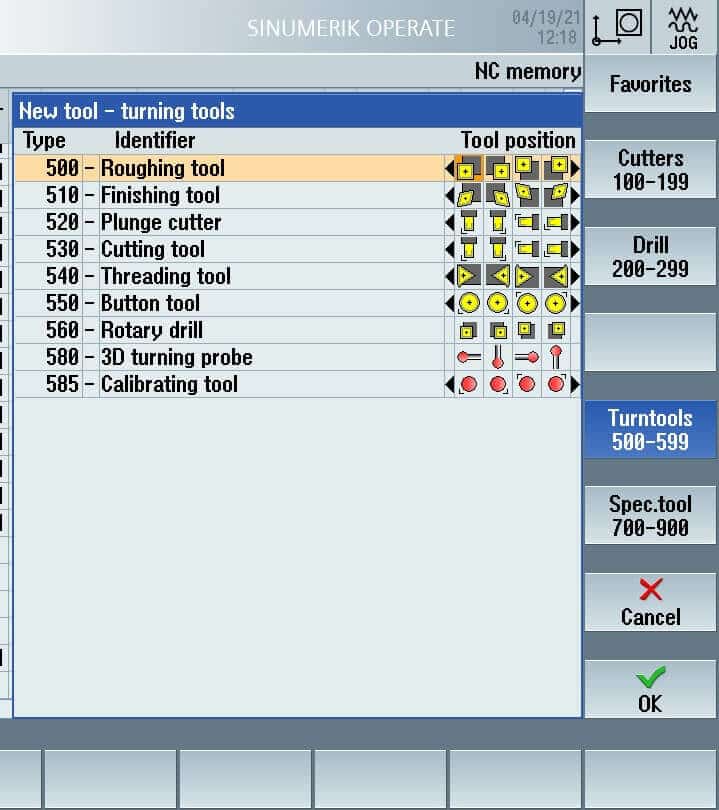

TYPES OF TURNING TOOL

If we are on a lathe, we will again find the family of favourites, the family of milling cutters 100-199, drills 200-299 and special tools. To these will obviously be added the 500-599 turning tools.

|

Turning tools. |