0 (0)

The SIEMENS intermediate level milling programming course is suitable for anyone working on a SIEMENS 840D control. The course complements the programming skills acquired in the basic course, which are useful for dealing independently with on-board programming of mechanical parts made in two-and-a-half axes and necessary to become skilled operators and programmers.

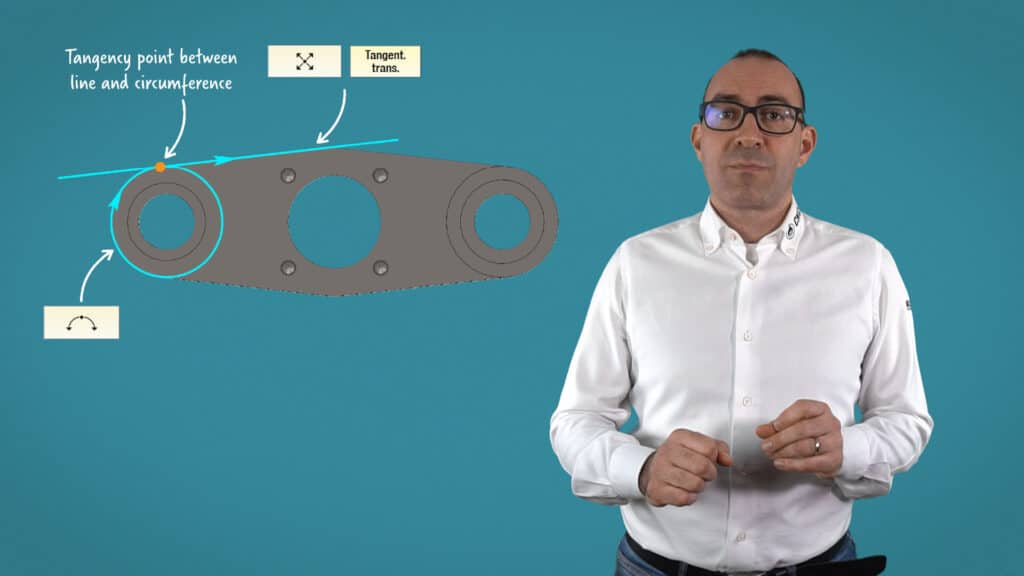

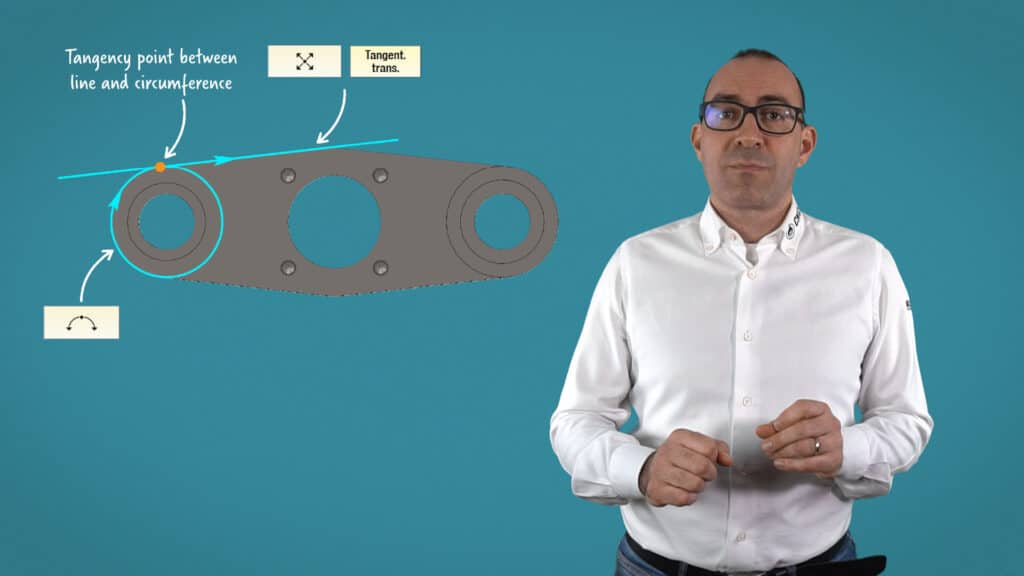

The Siemens CNC programming course in milling of intermediate level, is addressed to all CNC operators and programmers working on a SIEMENS 840D control. As this is an intermediate level course you will need to have a basic knowledge of the control at an operational level or possibly have followed our Operating on Siemens 840D course. You will also be required to have some basic knowledge of Siemens programming or have followed our Basic milling programming in G-codes course. In this course you will complete all the contour programming functions; starting with the unfamiliar but very convenient contour approach and departure functions: G147, G148, G247, G248, G347 and G348. We will go into detail about the various circular interpolations made available by Siemens to program contours more closely to the drawing (CR, CT, AR, CIP). If your drawing does have angles, the two lessons on the ANG angle function and polar co-ordinates will certainly come in handy.

To have a thorough knowledge of contour programming, it is necessary to know how to manage the correct feed rate along the trajectory using the CFTCP, CFC and CFIN functions. It is also essential to know how to manage the trajectory correctly with the exact stop and the continuous-path mode functions, to which we will dedicate specific lessons. In the last part of the course we will go into detail on the powerful contour milling cycles. With these we will carry out pockets with studs, workpieces with pivots and contouring or face milling using the continuous milling cycle. We will learn how to use in an advanced mode the contour editor and DXF importer.

Finally, there will be two lessons to learn how to program in SHOPMILL mode in order to have a complete knowledge of the tools that Siemens provides. The course will complete the programming skills acquired in the basic course and useful for dealing independently with on-board programming of mechanical parts made in two and a half axes and necessary to become specialised CNC operators and programmers.

There are no exercises in this course.

Subscribe to our Newsletter to stay updated and receive helpful articles and special offers

Puntotec Srl

Via Cavour, 2, 22074, Lomazzo (CO)

info@cncofcourse.com

P.IVA IT03918980123