Shopmill – Part 1

Description of SHOPMILL functions

INSIGHT

In today’s lesson we explored Siemens programming in SHOPMILL mode on a theoretical level. From what we have already seen in today’s class, it immediately appears how Shopmill programming allows one to be operational in a short time and without special knowledge of Siemens codes and functions.

This is a very useful tool, as we have seen! To help you understand the applications and peculiarities of Shopmill, I bring you a lesson from one of our previous courses. In the following video we gave our thoughts on when to use SHOPMILL and when to use G-code programming.

To conclude, I would say that the choice between G-code programming mode and SHOPMILL depends on many factors.

Certainly SHOPMILL can be a tool to get started quickly with programming even without special knowledge of programming codes and functions.

Programming in G-Codes is definitely the most complete; it allows us to manage every single aspect of processing with extreme autonomy, also considering the fact that in G-Codes mode we have all the same cycles available as in Shopmill mode.

TOOL CHANGE FUNCTIONS IN SHOPMILL

In SHOPMILL cycles, the tool change function and all M functions related to the coolant turn on are triggered. It is therefore necessary to set correctly in the tool table the type of coolant matched to the tool.

To do so, select the column for the coolant to be automatically activated when the tool change is complete.

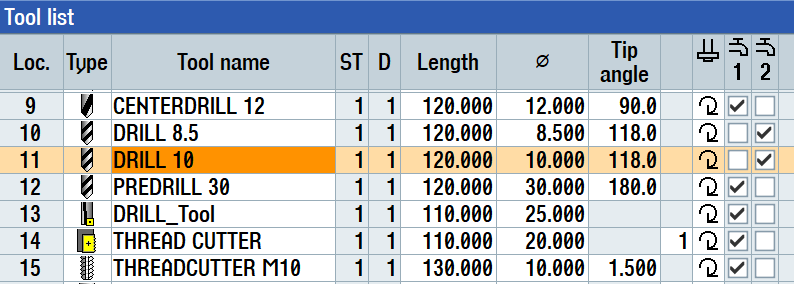

In the tool list you will find two columns with the tap symbol. Following the machine builder’s instructions, you should select the column for the coolant to be activated at the end of the tool loading procedure. It usually corresponds to external coolant and internal coolant through the machine taper.

The machine builder should have appropriately configured two machine data:

($MCS_M_CODE_COOLANT_1_ON e $MCS_M_CODE_COOLANT_2_ON) with M functions to be triggered when we selected coolant No. 1 or No. 2.

Coolant shutdown occurs automatically before the tool is stored. Again, the machine builder must have appropriately configured the M function combined with the shutdown of both types of coolant. In case you select both coolant icons, another machine data defines whether to activate both functions 1 and 2 or a third one that could be air. I therefore recommend consulting the builder’s documentation for the correct definition of tool-related parameters combined with use in SHOPMILL mode.