0 (0)

The Lathe machine course is mainly focused on the knowledge and use of tools and inserts. It aims to provide the various figures in the workshop with the necessary elements to manage the machine tool, making the best use of inserts and equipment. It will start from the primary objective of chip removal, i.e. production and therefore the chip volume, and will then address all aspects related to cutting parameters such as depth of cut, feed rate and cutting speed. The technical information for the correct choice of parameters based on the machining operation and the material to be machined will be provided. We will then move on to a description of turning tools and the geometric aspects of the tool that influence the chip formation process. This is a fundamental course for all lathe operators, enabling them to become fully aware of all technical aspects related to chip removal technology in turning.

The lathe machine course is an essential tool for learning turning technology with the right mix of technical skills and practical aspects of chip removal in turning. The lathe machine course aims to provide the various people who gravitate to the workshop with the necessary elements to operate the machine tool and make the best use of inserts and equipment.

It will start with a description of turning tools and the geometric aspects of the tool that affect the chip formation process (registration and rake angles). This part of the lathe machine course will be essential for learning about angles and geometries both for the correct selection of them and for entering data into the tool tables of numerical controls and CAM programs.

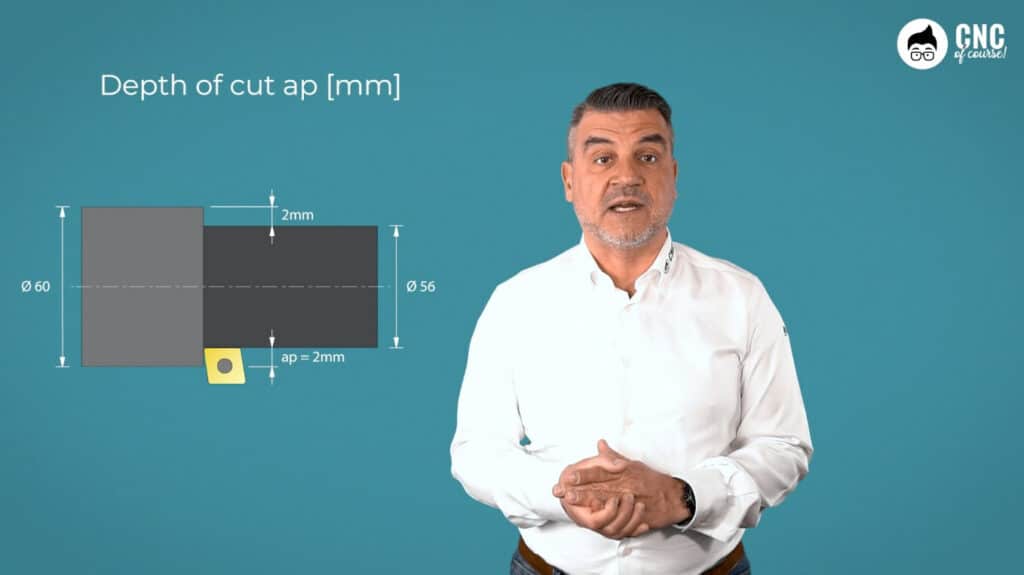

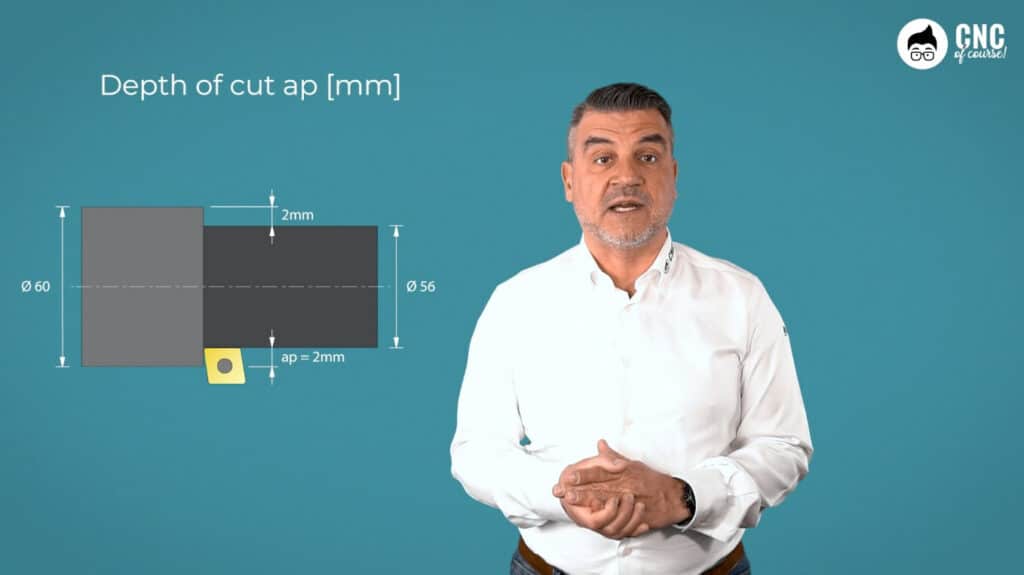

A specific section will address cutting parameters: depth of cut, feed rate and cutting speed. Some lessons will be entirely dedicated to the correct knowledge of cutting materials with a focus on cemented carbide, its manufacturing process and the correct quality selection based on the material to be machined. Once you know all the aspects involved in the turning process you will finish with the primary objective of chip removal, i.e., production and chip volume, learning how to properly select all the elements to get the maximum benefit from the machine and tool. This is an essential course for lathe operators to become fully aware of chip removal technology in turning.

There are no exercises in this course.

Subscribe to our Newsletter to stay updated and receive helpful articles and special offers

Puntotec Srl

Via Cavour, 2, 22074, Lomazzo (CO)

info@cncofcourse.com

P.IVA IT03918980123