Side rake angle

Full explanation of the side rake angle and its influence on the chip thickness, the cutting force and the chip formation.

INSIGHT

The side rake angle or cutting angle is, as we saw in the lesson, a very important aspect. It can influence the angle at which the chip is cut, depending on whether it is positive or negative. Positive side rake angles correspond to better and faster chip evacuation with less heat development in the cutting zone. On the other hand, the cutting edge will be fragile and unsuitable for heavy turning operations such as roughing.

A negative side rake angle, on the other hand, will have much greater resistance to heavy shear forces and stresses but slower evacuation, which will cause more friction and therefore higher temperatures in the cutting zone.

Generally speaking, it is advisable to use positive rake angles (sliding angles) in:

- finishing operations

- to limit the occurrence of vibrations

- when machining particular materials such as light alloys and thermoplastics

We will use a negative rake angle, if we want a strong insert capable of withstanding roughing or machining of tough steels, particularly hard materials or cast iron with interrupted or uninterrupted cuts.

The chipbreaker geometry

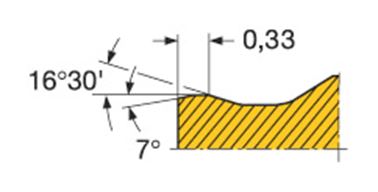

One thought that we would like to propose at this point is to analyse the role of the chipbreaker geometry on the value of the side rake angle. Can it influence the cutting angle? Let’s try to consider this image. As you can see, the chipbreaker geometry also has angles.

Those in the figure are an example taken by sectioning the cutting edge at a point along it. Once the insert is fixed on the corresponding tool, the angle of the geometry just mathematically adds to or subtracts from the cutting angle. In addition, we must not forget that the tool also has an inclination of a few degrees in relation to the axis of the workpiece. To be precise, screw clamping tools have a setting of 0°, as they are perfectly parallel to the axis of the workpiece. Meanwhile, lever clamping tools have a setting angle of minus 6°.

Side rake angle for CBN and ceramic inserts

In this respect, please note that for tools with CBN or Ceramic inserts, the setting is -8°. In fact, these inserts are harder and more brittle than solid carbide inserts. These inserts need a stronger and more negative setting because of this characteristic. All this leads us to say that knowing or calculating the effective cutting angle, i.e. the effective side rake angle and the angle at which the chip develops, is not so simple and immediate. In all likelihood, only the tool builder would be able to give us such information, which will also be important in the calculation of the power input, which we have discussed extensively in this lesson. Or in the magnitude of the forces that develop during turning. In general, positive cutting angles will correspond to lower forces and stresses and vice versa.

Finally, for now we can say that in the formula for calculating the power required by the machine tool to carry out a certain machining operation, the side rake angle is involved, as mentioned above, and as this angle varies the final result on the machine tool will also change. The power absorption will change for every 1% change in rake angle, more or less depending on the value of the cutting angle. If the side rake angle is negative, more power will be absorbed. If, on the other hand, the side rake angle is positive, less power will be required by the machine tool, even if the same chip volume is removed.