Working with the C-axis on a lathe with motorised tools is now a simple activity and accessible to everyone, especially if it is used for drilling. The situation is different if you want to carry out milling operations with the C axis without the Y axis and you are on large lathes. In these cases, the activity becomes more complex because the operation is made more difficult by the mechanics and inertia, as well as the dimensions and consequently the weights.

The customer who commissioned us to carry out a test before purchasing a vertical turning machine, Luigi Cantoreggi, owner of CAMU vertical turning and portal milling machines, knows this. To check the quality of machining with the C-axis, we will be carrying out a helical ramp threading performed with a thread mill. With the customer, we decided to carry out a thread milling, because apart from being a machining operation that he will have to carry out frequently for his productions, it is also a machining operation that requires the interpolation of C, X and Z axis. Luigi put a machine at our disposal for testing.

Feasibility test

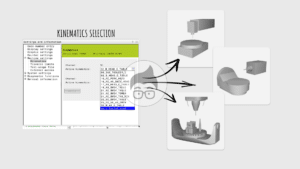

In the machining test we will make an inspection hole into which we will then screw a plug, but we will make the thread in a single cut with a thread cutter. In the first part of the hole we’ll actually do a lamination used to check the dimensions obtained with helical interpolation. We are going to execute the test on a Fagor 8065T, for programming we used the #FACE function that enables polar coordinates.

I’ll let you discover the result of the test by watching the video.

Enjoy!