In this article I would like to make a reflection on mainly young (but also not so young) people who want to enter the profession of CNC operator and programmer. Although the question “How to become a CNC operator and programmer?” may seem very superficial. It is in fact an obvious need of many young people who, after finishing school, are looking for a job, finding numerous job advertisements addressed to professionals in the machine tool sector. All those who work in this field are aware of the real need for CNC operators and programmers. It affects many businessmen and craftsmen on a daily basis, who complain about the lack of technical staff to equip and set up CNC machines.

I would like to give some useful tips to those who want to approach the world of numerical control machines, without presuming to say what needs to be done but simply sharing my personal experiences and those of young people I have met.

Let’s start by clarifying the professional figure.

Operator, machinist or CNC programmer?

We often hear about job offers for the above-mentioned figures, so first of all it is good to explain who they are and what they do. If we wanted to give a technical definition we could say that:

- CNC OPERATOR. This is the person in charge of setting up the CNC machines; starting with the unloading and loading of workpieces, up to the dimensional control of production and the routine replacement of tools subject to wear, acting on the wear correction parameters to compensate for tool wear;

- MACHINIST. This is the person who arrives at the machine during set-up. He will be in charge of setting up the tooling for the production changeover, loading the program into the machine and running the first parts to check that the machine is set up correctly;

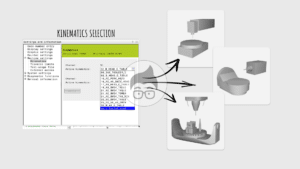

- CNC PROGRAMMER. This is the person who compiles the CNC program; writes the program using the tools at his disposal such as CAD-CAM, CNC editor and simulators to create the program and all the technical information to be sent to the machine and the machinist.

At this point it is necessary to clarify: the three professional figures would be better identified by the term JOBS. In fact, depending on the company and its procedures, one person may be responsible for programming, tooling and preparing the machine, or there may be three very different people. I have seen the latter in very large and structured companies. In some cases, the three figures even have different machine authorisation keys, precisely to allow operations limited to their own competences.

Now that it is clearer what CNC operator, machinist and programmer are going to do, let’s try to understand how to become one. The answer is very simple: MOTIVATION.

Although it may sound rhetorical, the only real key is to have the right motivation which will then lead you to the right determination.

But now let’s get into business!

What to do to become a CNC programmer

If I had the choice of where to start in order to become a CNC programmer, I would recommend a high school with a specific field of study and at least a mechanical one. Here you can choose according to what the school landscape around you has to offer. Speaking of schools, I must say that there are some very well equipped and with very good teachers. The advice I can give you is to ask to visit the laboratories provided and understand whether the school has invested in equipment. In addition to the traditional lathe to make a bit of chip, the CNC machines and any CAD-CAM stations should not be missing. Also ask how many hours will be devoted to the CNC machines; watching them switched off will not help you learn a profession.

If you attend the right school, you will probably not have much difficulty in finding a job either, because many companies take names directly from the schools.

But now we come to those who did not go to school for CNC machines or for mechanics in general. These are the people who have given me the greatest satisfaction in these years of teaching. They are the people who are sometimes even more motivated, because they first approach the subject out of necessity and then become passionate about it.

For the latter, the problem is that if they come to a job search with a CV that has no connection with the world of machine tools, they will certainly have little chance of being hired. At this point it will be necessary to break a vicious circle of “if I don’t work I will never have the experience, but without the experience I will never work”. Pun apart, the problem at this point will be to show a real interest in the subject and above all to be determined to learn and become a CNC operator or programmer.

What can we do?

The first thing I would recommend is to use job agencies that organise courses aimed at CNC machines. From my own personal experience, I have known many young people who have attended this type of course and who have quickly found their place in the machine tool world with excellent results. The advice is to evaluate the training course you are offered and assess its effectiveness in terms of both duration and content. In fact, a good course should certainly cover technical drawing, technology and finally the use and basic programming of numerical control. The minimum duration should be around 120 hours in order to effectively cover the above topics.

The second thing you can do is to build your professional career. Whether we are looking for a job or are already working, we must always bear in mind that we must never stop studying. To do this, there are many tools. We on this site are trying to create resources to learn and improve by allowing people to follow our courses, both in e-learning mode and by participating in classroom courses or specific workshops. At the following link you will find our online cnc courses. I also recommend you to look for training centres near you and take advantage of every possible resource to follow your personal growth path.

For the younger generation, I would also like to remind you to take advantage of the resources on social networks; there are Facebook groups and forums followed by very competent and helpful people. They are a free resource and certainly help to build up a knowledge, and in some cases also to find answers to technical questions, whether simple or not.

Obviously in this article I just wanted to include some suggestions, but I invite everyone to persevere; companies have a huge need of CNC operators, and this work allows you to combine a manual and concrete part with an intellectual one.