SHOPMILL Vs G-Codes

G-codes compared with SHOPMILL programming

INSIGHT

In today’s lesson I have reintroduced part of the “Operational” lesson in which we have already covered the topic of SHOPMILL Vs G-codes. It seemed important to me before starting with programming in G-codes to discuss and understand together the differences and alternatives that are proposed to you by SIEMENS for programming. In the next lesson we will address the programming alternatives in more detail. In today’s lesson, however, I wanted to focus on G-code programming compared to SHOPMILL programming.

But let’s first clarify and try to understand what SHOPMILL is.

WHAT IS SIEMENS SHOPMILL?

SHOPMILL is a highly conversational language developed by SIEMENS using the same cycles already found in G-code programming, but developing an operation-oriented format. As you saw in the video, while G-codes require a sequence of instructions written block by block, SHOPMILL encloses everything within the cycle with the intent of creating a very compact program that is as operationally oriented as possible using fixed cycles. Fixed cycles, as you can imagine, are instructions that perform entire operations by defining a set of parameters necessary to perform the required machining operations.

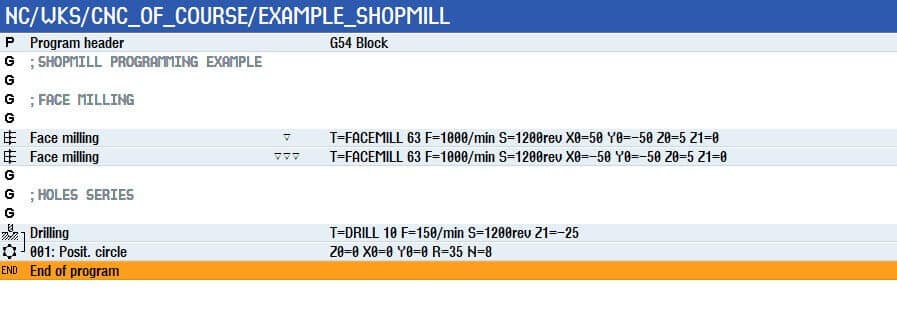

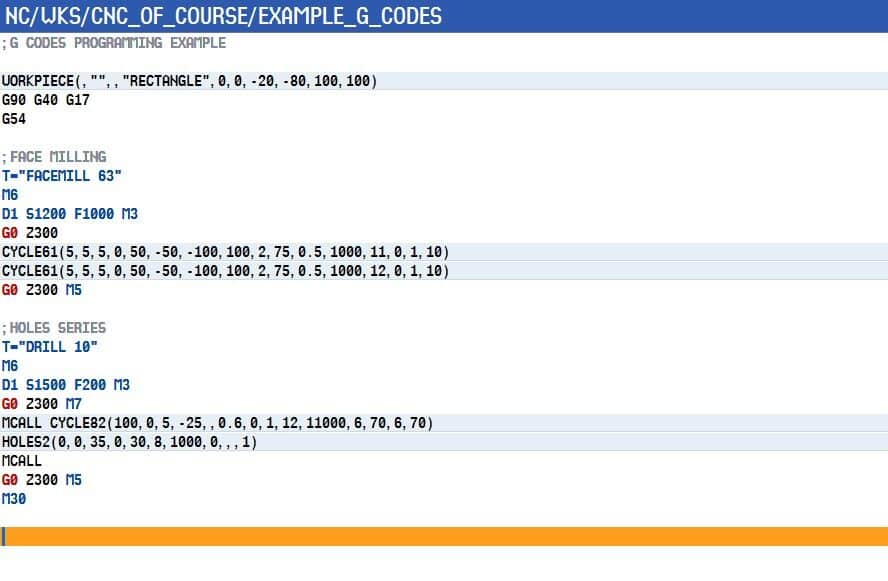

Here I put the same machining programmed in SHOPMILL and just below the same program but written in G codes. You can also find the two programs among the lesson files for download.

SHOPMILL EXAMPLE:

G CODES EXAMPLE:

In the two examples, face milling and a series of circular holes are performed. For both machining operations, fixed cycles were used, with the difference that in SHOPMILL the cycle also performs the tool call, the definition of the technological parameters, and the approach/departure from machining. In the G-code version, the cycle performs only the machining, while tool selection and technological parameters are programmed in the blocks preceding the cycle.

From here we can see that the functionalities are exactly the same; programming in Siemens SHOPMILL does not preclude any of the functionalities of programming in G-codes. The difference is mainly made by the type of machine and the types of machining, as also described in the lesson video. Certainly it can be said that programming in G-codes is more versatile and complete: all machining operations that do not fall within the capabilities of fixed cycles will still always have to be programmed in G-codes. The reason we took a course on programming in G-codes is related to the fact that if you learn to program in G-codes you will probably not even need an additional course to learn shopmill, but the reverse concept does not apply.

One last necessary clarification concerns Siemens SHOPMILL or SHOPTURN: SHOPMILL is the milling version of the conversational, SHOPTURN is the turning version. In the video and in the in-depth discussion, I always mentioned SHOPMILL because the course is aimed at milling.