Hi, if you’ve landed on this page you’re probably looking for a CNC course. Don’t worry, you’ve come to the right place! But first of all, we need to introduce ourselves and, above all, clarify a few things about CNC courses. Let me first introduce myself: I am Paride, the founder of CNC of course. Although I’m not very fond of introductions, it seems right to me to tell you something about myself first.

I’ll start at the beginning because it will help me to let you understand the spirit in which I created CNC of course. Unfortunately I have to go back to when I was a kid. Yes, because I had the good fortune to grow up in a mechanical workshop; since I was a child my father used to take me to his workshop and while he was working on the machine tools he would give me a few jobs to keep me busy with very simple things, but for a 10 year old boy they already seemed like big tasks.

Things got more serious in the summer of my 14th birthday, when I finally made my first workpiece on the traditional turning machine, a great satisfaction even though it was very simple and – to tell the truth – not very well made… But for a long time I kept it on my desk as a small trophy.

Why did I tell you about my youth?

Because my father had CNC machines and although I practically had them in the house, I never put my own program into the machine and the whole time I worked there, programming the CNC machines was off-limits to me. I would change inserts, make a few small corrections and it always seemed so complicated to think about making a part completely on my own! Where do I start? The program, the work zero offset, the tools…

That’s when I started to develop the idea that I would be a CNC programmer for a living. But I also knew that to do that I would need to take CNC courses and gain experience on the machine. So after finishing university I worked in various jobs for a few years, always in contact with CNC machines and learning as much as I could by attending CNC courses wherever I could find them. I gradually realised that I wanted to be a trainer, so that everyone could do this wonderful job.

So in 2005 my life changed: I opened my own small CNC programming and training business. I have to say that the first few years were also the hardest, because obviously the workshops were not waiting for me. So for a few years I went back to working as a weekend waiter, which I had done during my university studies. Without saying too much, the years went by, grinding out all kinds of programs and adding a new numerical control to my skills each time.

In recent years, thanks to the collaboration with important machine tool builders, I have started to travel the world; I have held courses in some of the most important international companies and in the most varied sectors. The United States, Sweden, Russia, Germany, France and China are just some of the countries I have worked in. But wherever I went, I always noticed one thing: we all had something to learn, me first!

So in 2019 we finally published the first online CNC course, officially founding CNC of course.

Here is the CNC course you are looking for

The goal of CNC of course is to give voice to professionals in this sector by making their skills available to everyone. Giving the possibility to anyone to follow a CNC course to offer the opportunity to grow.

We know that studying and attending CNC courses, even in the evenings, is tiring. So the second requirement that CNC of course had to have was to combine the useful with the enjoyable: explaining serious and very technical things in simple, light language and, why not, having a bit of fun too. Hence the idea of our assistant Paolo.

But now back to us.

What courses will you find on CNC of course?

If you go to our CNC courses page you will find a list of our available courses, but first let me give you a little more explanation.

To say CNC course is very general and requires further elaboration; the world of CNC machines is vast, the numerical controls are varied and so it becomes difficult to know where to start and which CNC course to choose. If you are already working on machine tools, everything is easier and you will most likely have a clear idea of what you are looking for. Are you working in a workshop equipped with SIEMENS CNC machining centres? So you will most likely be looking for a SIEMENS milling course and not a generic CNC course. If, on the other hand, you are looking for a generic CNC course, it means that you do not yet have a precise idea of the type of machine you are going to work on, turning or milling machine, and above all with which numerical control.

Now your question will surely be: “What are the differences between one numerical control and another?”

It would take more than a blog article to answer this question in depth, but without going too far into detail, I will try to give some indications to those approaching the world of CNC machines. There are all kinds of numerical control machines of various models and brands. Fortunately, the numerical controls installed on the various machines can be reduced to around ten. Of these ten, 80% of the machines have one of these controls: SIEMENS, FANUC, HEIDENHAIN, FAGOR and MITSUBISHI.

Looking at the Italian market, I should also add SELCA, which, although no longer in production, has a very high installed base, being a truly valid Italian control. Obviously there are not only these controls, but from a numerical point of view the ones I have mentioned are the most popular. In addition, there are machine builders who have also developed their own numerical control, such as OKUMA, MAZAK and HURCO, to name but a few.

At this point the following question would be legitimate.

Which numerical control do I start with to do a CNC course?

Even asking yourself this question is a step forward. Yes, because at this point it is starting to become clear that when we talk about a CNC course, it is important to match the type of numerical control.

Now here someone could reply by saying: ISO programming.

What is ISO programming?

Let’s specify right away that ISO means the standard 6983: this is a standard that defines guidelines for programming CNC machines. Let’s be clear that ISO is so generic that it stops at the main G functions and is not enough to meet the current needs of any machine tool. Just for the record, the last revision of the standard was in 2009, so CNC manufacturers have had to implement other functions to fill the gaps in the norm. To cut a long story short, some CNC builders referred to the ISO standard as far as possible, but as soon as they got into the specifics of canned cycles or advanced functions, each builder had to develop his own functions.

At this point I would say that it may be useful to answer the following question.

Which numerical controls are based on ISO?

First of all, we can say that Fanuc, Mitsubishi and Siemens are the numerical controls that comply most closely with the ISO standard. To be precise, they have also extended their programming capabilities by integrating proprietary functions and languages to meet production requirements. Fanuc did this by introducing Manual Guide and Siemens by introducing ShopMill/Shopturn. Now let’s say a few words about the other numerical controls: Heidenhain, Fagor and Mazatrol are controls where the primary programming choice is through their proprietary programming language. But if you wish, all three, in different ways, could also be programmed in ISO mode.

Now some of you may be thinking: “Well, I’ll do a CNC course in ISO programming and I’m all set”.

Doing a CNC course aimed at a control based on ISO language could be a sensible solution, especially if you want to start off with a CNC course and enter the world of machine tools. I will therefore choose a control that, as well as being one of the most widely used, is also based on ISO, aware that in any case, in order to pass from one control to another, as well as changing all the management and navigation in the control, only some parts of the programming functions will be common, all the rest will be different precisely because of the limits linked to the ISO standard.

So where do I start to become a machine operator?

Generally speaking, we have already dealt with this subject in another article, but staying on the subject of training, let us try to list the skills that an operator or programmer on CNC machines must have:

- TECHNICAL DRAWING. An operator must certainly be able to read the technical drawing in all its aspects; all the information about our parts to be produced is written there! So you have to be familiar with the views, the geometric and dimensional tolerances, the various symbols and the degrees of roughness;

- TECHNOLOGY. Creating a CNC program must be the last of your steps to become an operator or programmer. The first is to learn how to recognise tools, know how they work, the materials of the tools and the materials to be machined to then correctly choose the cutting parameters and not only that, know how to make choices based on productivity. I can help you with this: in the online CNC courses page, you will find a really good course on turning technology, covering all aspects of turning technology. From tool selection to tool materials. The cutting parameters, how to choose, calculate and apply them. It is not a generalist course; I myself, who worked alongside the teacher who prepared it, learned a lot. I would even say that to make it your own it is necessary to watch it several times and always have it available when working in the workshop. If you’re looking for a more generalist course, it’s not for you, it’s very technical and in-depth;

- BASIC KNOWLEDGE OF THE SUBJECT. Before jumping straight into programming, you need to know the terminology, how CNC machines work, the axes, an overview of the various numerical controls and their peculiarities;

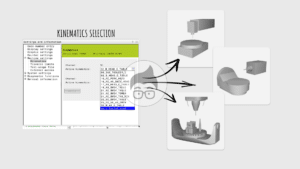

- OPERATION AND USE OF THE MACHINE. Here we enter the CNC world and we do so by learning all the operating procedures that an operator must do to start production: resetting tools and origins, navigating and moving around in the numerical control, procedures for resetting and restarting the program, defining tool data… In short, acquiring the skills that an operator on CNC machines must have. But a choice must be made: for which numerical control? This brings us back to our previous thoughts. At the time of writing, we have created a specific operating course for SIEMENS 840D. But why Siemens and not others? In time we will certainly make a Fanuc or other CNC operating course, but SIEMENS, as well as being very popular, offers the possibility for anyone to have a free simulator installed on their PC. This is a huge advantage! Doing a CNC course but not being able to test and try out what you have just learned makes everything more difficult. Again it is very technical and in-depth and with many videos actually filmed on the machine;

- CNC PROGRAMMING. Once you have learnt what lies behind a program and the machine tooling activities, you come to programming. Here, as mentioned above, I will necessarily have to make choices. Turning or milling machine and for which CNC. If I choose a CNC course based on an ISO ‘friendly’ control, I will have some common ground with other ISO-based numerical controls. We currently have three CNC programming courses available. Siemens 840D Milling – BASIC, Heidehain Milling and Fagor 8065 Turning but specific to C-axis and Y-axis machining. The latter is not recommended if you are starting from scratch, but it is recommended for all turning operators who are already working on lathes with Fagor 8065 control and want to learn more about C-axis and Y-axis machining. I would say that if you are starting from scratch, after having done the Siemens operating course it would be more than recommended to continue with the SIEMENS 840D milling course. With this course you will already be able to make numerous programs and thanks to the exercises that you can download you will also be able to practice and try them out yourself.

In conclusion

Here I have set out the skills required of a CNC machine operator or programmer; these points should also be milestones or, better still, real goals for your professional development. Obviously, all this must be accompanied by practice, hands-on experience and “eating chips”. To do this you need to enter the workshop, but to enter the workshop you need to have a minimum of skills, thus entering a vicious circle. To break this vicious circle, you need to start…

But, start from where?

Start where you can: if you don’t have a job, building technical skills is a start, taking our CNC courses, but also buying and reading books is a start. Participating in webinars or classroom courses are all things you can do just to break the vicious circle.

We are only giving you a few elements for your professional growth in the world of CNC machines and, if you were to ask me for advice on which CNC course to follow among those present on CNC of course, I would say to start with the Siemens 840D operating course and then the Siemens basic milling course. But remember, these courses are just the beginning!

Starting, that is the first step, persevering and believing are the other.